ORDER NOW

CALL 800-827-7455 OR LOGIN TO YOUR ACCOUNT

BRINGING MORE VALUE TO YOU AND YOUR CUSTOMERS

• 100% installation of the latest design roller bearing assemblies for maximum lifter durability and longevity.

• Early-style heads receive NEW updated valve seats which are press-fit to tighter specifications to ensure seat retention.

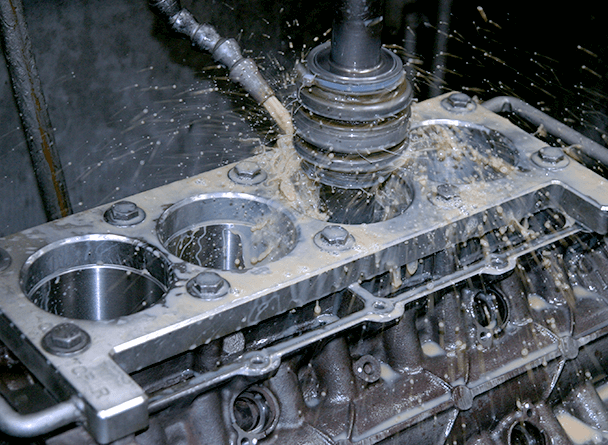

• Block and head surface finishes are machined to a 50-150 Rz finish to prevent external leaks.

• MLS (Multi-Layered Steel) head gaskets ensure superior protection against gasket leakage. Our MLS gasket is also more robust to maintain the correct compression ratio.

• Torque-plate honing, provides cylinder wall geometry that matches the cylinder head as a complete running assembly, for improved ring sealing.

• Re-engineered JASPER piston design features:

- Full-floating pin to reduce pin bore scuffing.

- Twice the piston skirt (thrust area) for improved durability and reduced piston scuffing tendency.

- Graphite coated piston skirts help prevent piston scuffing and dry start-up.

- Additional center skirt drain backs provide 3X more oil return.

• Nitrided valve upgrade improves heat resistance and reduces valve guide wear.

• To prevent bearing damage, crankshafts are machined and micro-polished to JASPER’s exact and proven specifications for improved, more precise oil tolerances and longer bearing life.

• High-temperature fluoroelastomer polymer (FPM) rear seal is installed to prevent oil leaks.

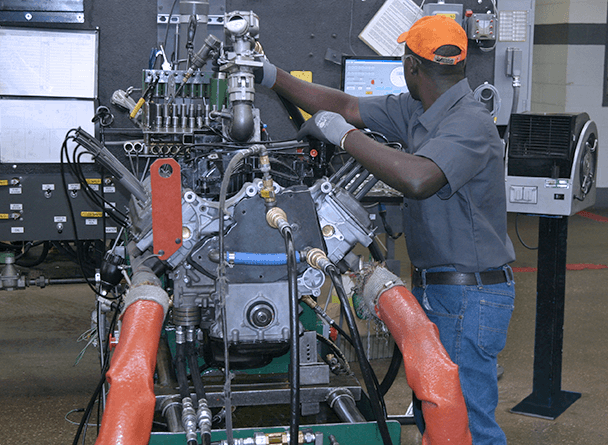

• Live-Run Testing, with Data Acquisition and other assessments for your assurance of reliability, includes:

- Compression

- Vacuum

- Oil Pressure

3 Year / 100,000 Mile Nationwide

Transferable Warranty

upon request. Specifications subject to change without notice.

Product Videos

Jasper Engines & Transmissions - Chrysler 5.7L HEMI Piston Design Update

Jasper Engines & Transmissions - Chrysler 5.7L Hemi Valve Seat Update

Jasper Engines & Transmissions - Chrysler 5.7L HEMI Head Gasket Update

Chrysler 5.7L Hemi Engines

Value-Added Quality Improvements from JASPER

Issue / Concern:

Lifter/Roller Failure

JASPER Solution:

-

100% installation of NEW (15-needle) roller bearing assemblies. The pin is improved with a through-hardening process followed by a case-hardening procedure for maximum lifer durability and longevity.

Dropped Valve Seats

-

Early-style heads receive tighter press-fit seats to ensure seat retention.

Head Gasket Leaks

-

Surface finish on heads and blocks are machined to a 50-150 Rz finish to protect against external leaks.

-

Installation of MLS (Multi-Layered Steel) head gaskets with a larger firing ring bore to improve sealing and more robust in design to maintain OE compression ratio.

Oil Consumption

-

JASPER includes a stronger, more robust piston ring pack for greater durability, better heat resistance, and improved oil control as compared to OE.

-

Torque-plate honed to simulate cylinder bore distortion, which occurs after block/head assembly, ensuring correct bore roundness.

-

Additional center skirt drain backs provide 3X more oil return.

Dry Start-up and Piston Scuffing

- Full-floating pin to reduce pin bore scuffing.

- Twice the piston skirt (thrust area) for improved durability and reduced scuffing tendency.

- Graphite coated piston skirts help prevent piston scuffing and dry start-up.

Valve Guide Wear

-

100% installation of NEW nitrided engine valves for improved heat resistance and reduced valve guide wear.

Low Oil Pressure/Knocking

-

Micro-polished crankshafts are machined to exact tolerances for improved, more precise oil tolerances and longer bearing life.

Oil Leaks and Runability Issues

-

High-temperature fluoroelastomer polymer (FPM) rear seal is installed to prevent oil leaks

-

Every engine is live-run tested to verify proper compression, vacuum, and oil pressure. JASPER also performs a black light leak test to ensure the unit is leak-free.

MDS Delete

- JASPER offers MDS Delete as an option for select Ram 1500 5.7L Hemi engines.

- MDS Delete engine will have a Non-MDS Cam, 16 standard lifters, and MDS solenoid plugs installed.

- MDS Delete option is 49-state compliant. Not legal for use or sale in California.

- JASPER includes a Diablo programmer with all MDS Delete engines.

- Diablo programmer is 50-state legal and available for purchase with standard replacement engines. (CARB E.O. D-770).