ORDER NOW

CALL 800-827-7455 OR LOGIN TO YOUR ACCOUNT

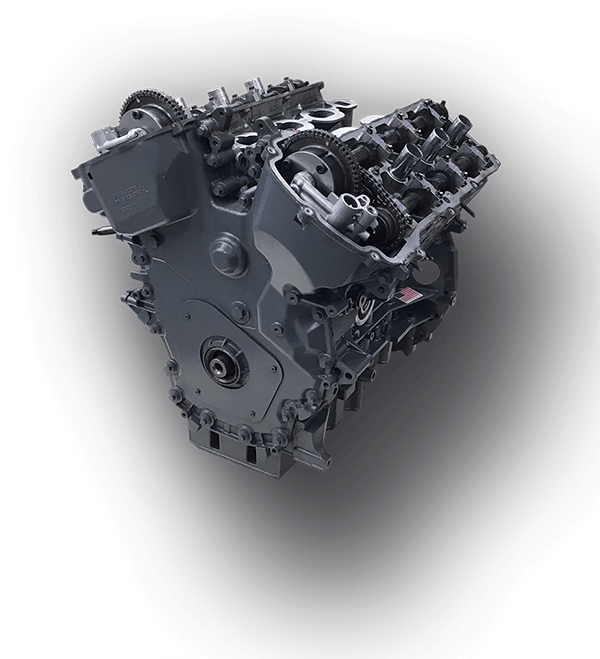

JASPER® OFFERS THE FOLLOWING FORD V6 ECOBOOST / DURATEC APPLICATIONS:

3.5 EcoBoost | 3.5 Duratec | 3.7 Duratec

JASPER UPDATES

- JASPER® updates all roller design primary chains to the improved silent chain design. This prevents excessive wear that is common with roller chains.

- 100% installation of the latest design water pump for transverse-mounted applications.

- JASPER-engineered pistons include a smooth, fully-machined, anodized crown that provides a thermal barrier and reduces carbon buildup.

- JASPER’s piston design includes additional oil return holes (14 total) to increase oil drain back by 250%, or greater, to reduce oil consumption and prevent oil rings from sticking.

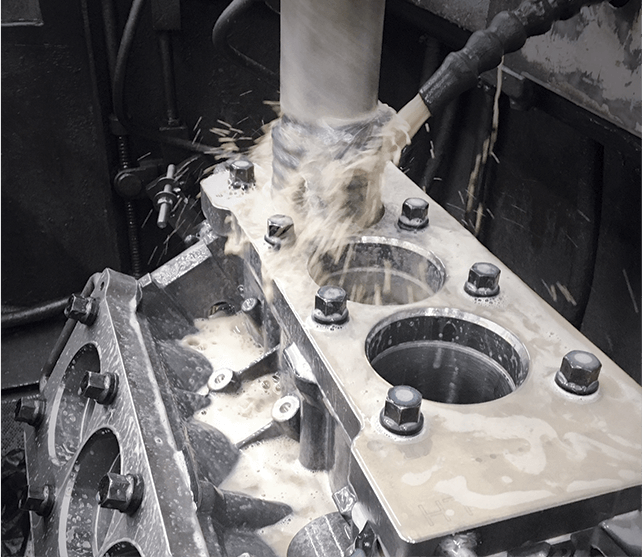

Torque Plate Honing

JASPER’s pistons for the Ecoboost engine are forged aluminum and excel in both strength and durability.

JASPER’s robust, two-piece, 2.0mm oil ring has improved oil control.

JASPER piston rings include a steel top ring with a large surface area of 1.5mm and a coating for longevity and less friction. An increased axial height on the steel top ring creates better sealing and heat conductivity.

An accumulator groove is machined into the piston to decrease the pressure between the 1st and 2nd ring land, preventing the upper (compression) ring from unseating at higher RPMs.

JASPER’s piston skirt surface area is 30% wider to improve durability and promote scuff resistance.

100% torque-plate honing, utilizing a torque plate and ARP2000® bolts, provides cylinder wall geometry that matches the cylinder head as a complete running assembly, for improved ring sealing and reduced piston and cylinder wall wear.

JASPER’s robust, two-piece, 2.0mm oil ring has improved oil control.

JASPER piston rings include a steel top ring with a large surface area of 1.5mm and a coating for longevity and less friction. An increased axial height on the steel top ring creates better sealing and heat conductivity.

An accumulator groove is machined into the piston to decrease the pressure between the 1st and 2nd ring land, preventing the upper (compression) ring from unseating at higher RPMs.

JASPER’s piston skirt surface area is 30% wider to improve durability and promote scuff resistance.

100% torque-plate honing, utilizing a torque plate and ARP2000® bolts, provides cylinder wall geometry that matches the cylinder head as a complete running assembly, for improved ring sealing and reduced piston and cylinder wall wear.

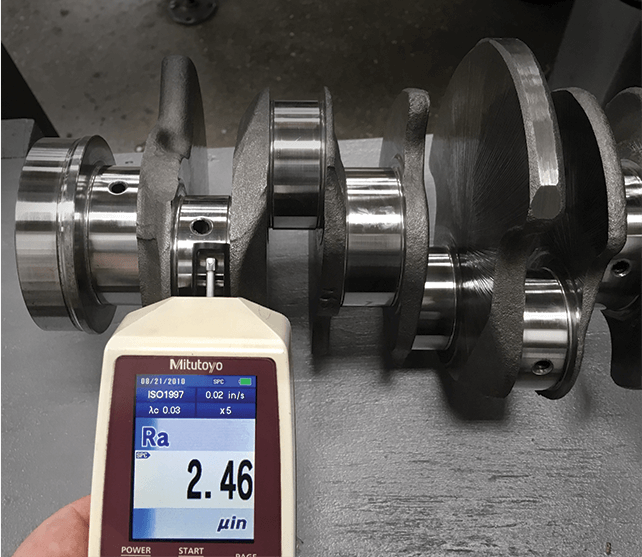

Crankshaft Journal Ra Finish

Camshafts are spray welded and machined to exact tolerances. Cam bores are machined with a specially designed, coolant fed CNC machine. These processes ensure precise specifications are met regarding bore alignment, size, and surface finish.

All camshaft lobes receive a Manganese Phosphate coating, providing added wear protection.

JASPER 100% installs a proprietary anti-friction, wear-resistant polymer coating on bearings to reduce dry start-up and increase longevity.

100% installation of high-strength, class 12.9 rod bolts to eliminate stretching, preventing possible bearing failure.

Thicker, fluoroelastomer (FKM) MLS head gaskets are installed, with new head bolts, along with better block and head surface finishes (50-150 Rz), to prevent leaks and maintain the correct compression ratio.

All camshaft lobes receive a Manganese Phosphate coating, providing added wear protection.

JASPER 100% installs a proprietary anti-friction, wear-resistant polymer coating on bearings to reduce dry start-up and increase longevity.

100% installation of high-strength, class 12.9 rod bolts to eliminate stretching, preventing possible bearing failure.

Thicker, fluoroelastomer (FKM) MLS head gaskets are installed, with new head bolts, along with better block and head surface finishes (50-150 Rz), to prevent leaks and maintain the correct compression ratio.

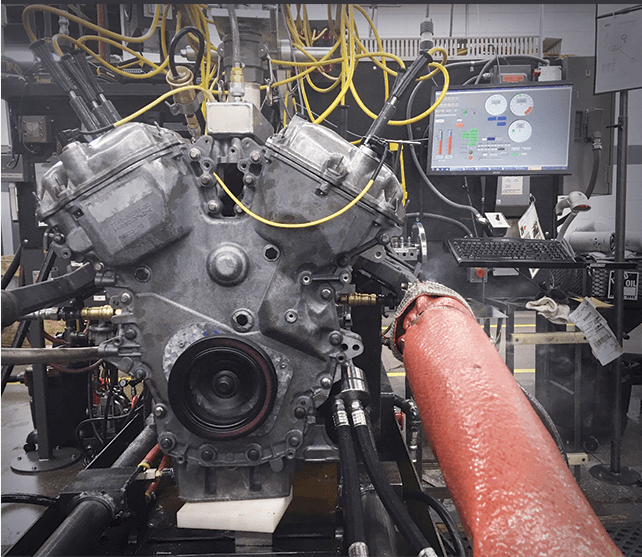

Live-Run Tested

Crankshaft rod and main journals are micro-polished to an Ra finish of 10 or less for improved bearing oil clearance and reduced wear. Crank seal areas are polished to a finish of 10-20 Ra to prevent leaks and increase seal longevity.

100% installation of NEW nitrided valves on Duratec applications for improved heat resistance and reduced valve guide wear.

JASPER installs an Inconel (Nickel- chromium-based superalloy) exhaust valve on Ecoboost applications to compensate for the boosted GDI’s increased in-cylinder temperatures and high pressure.

Live-run testing, utilizing data acquisition with other assessments for your assurance of reliability includes: compression, vacuum, oil pressure, and (VVT) cam actuator testing.

Live-run testing is followed with a blacklight leak test to make sure there are no leaks around gasket and seal areas.

100% installation of NEW nitrided valves on Duratec applications for improved heat resistance and reduced valve guide wear.

JASPER installs an Inconel (Nickel- chromium-based superalloy) exhaust valve on Ecoboost applications to compensate for the boosted GDI’s increased in-cylinder temperatures and high pressure.

Live-run testing, utilizing data acquisition with other assessments for your assurance of reliability includes: compression, vacuum, oil pressure, and (VVT) cam actuator testing.

Live-run testing is followed with a blacklight leak test to make sure there are no leaks around gasket and seal areas.

FORD 3.5L ECOBOOST

Ford 3.5L Ecoboost

FORD 3.5L DURATEC

Ford 3.5L Duratec

Product Videos

Mazak HCN-6800 CNC Machine

EcoBoost Piston Design

Ford V6 EcoBoost / Duratec

Value-Added Quality Improvements from JASPER

Issue / Concern:

Timing Chain Failure

JASPER Solution:

- JASPER® updates all Roller design primary chains to the improved Silent chain design. This prevents excessive wear that is common with the roller chains.

- Silent chain updates include replacement of chain guides; VVT; Crank Gear.

Water Pump Failure

- 100% installation of latest design water pump for transverse-mounted applications.

Piston & Rings

- Stronger, JASPER-engineered pistons have a smooth, fully-machined, anodized crown that provides a thermal barrier and reduces carbon buildup.

- JASPER’s piston design includes additional oil return holes (14 total) for increased oil drain back, to reduce oil consumption and prevent the oil rings from sticking.

- JASPER installs a robust, two-piece 2.0mm oil ring for improved oil control.

- JASPER piston rings include a steel top ring that has a larger surface area of 1.5MM and a coating for longevity and less friction.

- JASPER’s steel top ring has an increased axial height for better sealing and heat conductivity.

- An additional accumulator groove is machined into the piston to decrease the pressure between the first and second ring land, preventing the upper (compression) ring from unseating at higher RPMs.

- EcoBoost Only: JASPER-engineered pistons are forged aluminum to increase strength and durability.

Cylinder Bores

- 100% torque plate honing of engine block utilizing a torque plate and specially-designed, ARP2000® bolts, provides cylinder wall geometry that matches the cylinder head as a complete running assembly for improved ring sealing.

- JASPER-designed pistons have a 30% wider piston skirt surface area to improve durability and promote scuff resistance.

Cam Bore Wear

- Camshafts are spray welded and machined to exact tolerances.

- Cam bores are machined with a specially designed, coolant fed CNC machine.

- These processes will maintain tight specifications on bore alignment, size, and surface finish.

Cam Lobe Wear

- All camshaft lobes are given a Manganese Phosphate coating to assist in added wear protection.

Main and Rod Bearing Wear

- 100% installation of a proprietary anti-friction wear-resistant polymer coating on bearings to aid in dry start-up and increased longevity.

Head Gasket Failure

- JASPER installs a thicker, fluoroelastomer coated MLS (Multi-layer steel) head gasket.

- Block and heads are resurfaced to a 50–150 Rz finish.

- 100% installation of NEW torque to yield head bolts.

Rod Bearing Failure

- 100% installation of high-strength, Class 12.9 rod bolts to eliminate stretching, which can lead to bearing failure.

Low Oil Pressure/Knocking

- Crankshafts are machined and micro-polished to exact tolerances for improved bearing oil clearance and reduced wear.

Valve Guide Wear

- 100% installation of NEW nitrided valves for improved heat resistance and reduced valve guide wear.

- EcoBoost Only: 100% installation of Inconel exhaust valves with a Stellite face to withstand the heat generated by this turbo GDI engine.

Runability Issues and Fuel Leaks

- 100% live-run tested to verify proper timing, compression, vacuum, and oil pressure.

- 100% tested intake and exhaust cam actuators to verify proper performance.

- 100% black light leak tested to ensure the unit is leak-free.

Hits: 662333